Introduction:

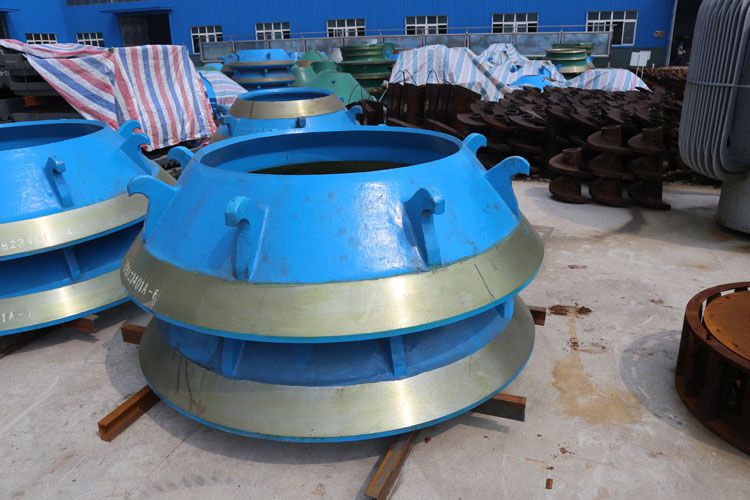

We offer a wide range of concave and mantles for all OEM manufacturer cone crushers. The critical factors for cone crusher parts are the open and closed side feed settings.

We offer a wide range of concave and mantles for all OEM manufacturer cone crushers. The critical factors for cone crusher parts are the open and closed side feed settings.

The manganese content is critical to the wear life of your crusher parts and the cost efficiency of your operation. Manganese content can range between 9% - 24% and is usually referenced as;

14% = 13-14% MN

18% = 17% - 19% MN

21% = 21% - 24% MN

Castings with any of these manganese percentages could be suited to your application, it is very much dependant on the material type you are processing. Using a higher percentage of manganese for your cone crushers concave and mantle doesn't necessarily mean that it will last longer, it depends on the right match. It is important to remember that manganese must "work-harden" for optimum performance, which should be matched with material hardness. The hardness & abrasiveness of the rock to be crushed should determine the manganese content for your operation. Be sure to match the profile to your crushing needs and if you are unsure ask our experienced sales representative at Wear and Spare Parts.